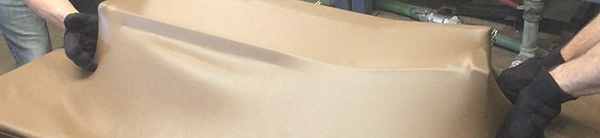

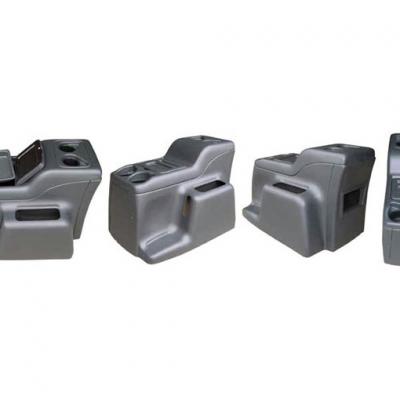

Thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it into a specific shape using a mold. While thermoforming is often associated with the production of small and medium-sized parts, it also offers many advantages for the production of large parts. In this article, we'll explore the advantages of thermoforming for large part production.

Cost-Effective

One of the main advantages of thermoforming for large part production is its cost-effectiveness. Thermoforming molds are typically less expensive to produce than injection molds, making it a more cost-effective option for large parts. Additionally, the thermoforming process is generally faster and more efficient than other methods, allowing for larger production runs at a lower cost per part.

Design Flexibility

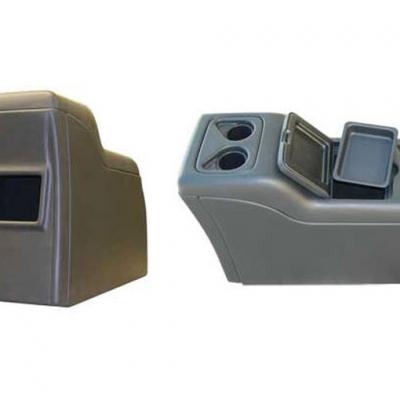

Thermoforming also offers greater design flexibility for large parts than other manufacturing methods. Thermoformed parts can be easily customized to meet the specific design requirements of each part, including size, shape, and material thickness. This allows for greater design flexibility and the ability to create unique parts and components.

Lightweight

Thermoformed parts are also lightweight, making them an attractive option for large part production. Lightweight parts offer several advantages, including reduced shipping costs, improved fuel efficiency in transportation, and reduced strain on equipment and infrastructure.

Durability

Thermoformed parts can also offer improved durability over other materials. Thermoformed parts can be designed to be impact-resistant, and they can also withstand exposure to harsh environments, such as extreme temperatures, UV rays, and chemicals. This makes them ideal for use in large parts that are exposed to harsh conditions.

Sustainability

Thermoforming is also a more sustainable option for large part production than other manufacturing methods. Thermoforming can be used with a wide range of materials, including recycled materials, reducing waste and environmental impact. Additionally, the thermoforming process can be designed to minimize energy consumption and reduce greenhouse gas emissions.

Conclusion

Thermoforming offers many advantages for the production of large parts, including cost-effectiveness, design flexibility, lightweight, durability, and sustainability. As manufacturers seek ways to reduce costs, improve efficiency, and reduce environmental impact, thermoforming will likely continue to play a key role in large part production. If you're looking for a cost-effective, lightweight, and sustainable option for your large part production needs, consider thermoforming.